THE FACTORY

From Occitania to the four corners of the world

Born in southern France, the Lâg brand aimed to develop internationally. At the Lâg factory located in the village of Bédarieux, 12 people were dedicated to manufacturing guitars in a 500 m² workshop. The brand wanted to take the next step by exporting around the world and opened its own factory in Tianjin, China.

With 30 years of experience in guitar manufacturing, Steve Kim stands as the perfect leader to oversee the factory and its 110-member team. This cohesive staff, proud of their longstanding commitment since the inception of the factory, fosters a harmonious environment where mutual understanding thrives and where the quality of work life resonates with overall well-being.

By his side, Maurice Dupont, a virtuoso luthier, personally optimized the manufacturing processes of the factory. Crowned as the best craftsman in France in 1981, he has successfully infused his passion for wood. The soundboards are sorted, tested, and each one is meticulously inspected to verify its tension and aesthetic quality.

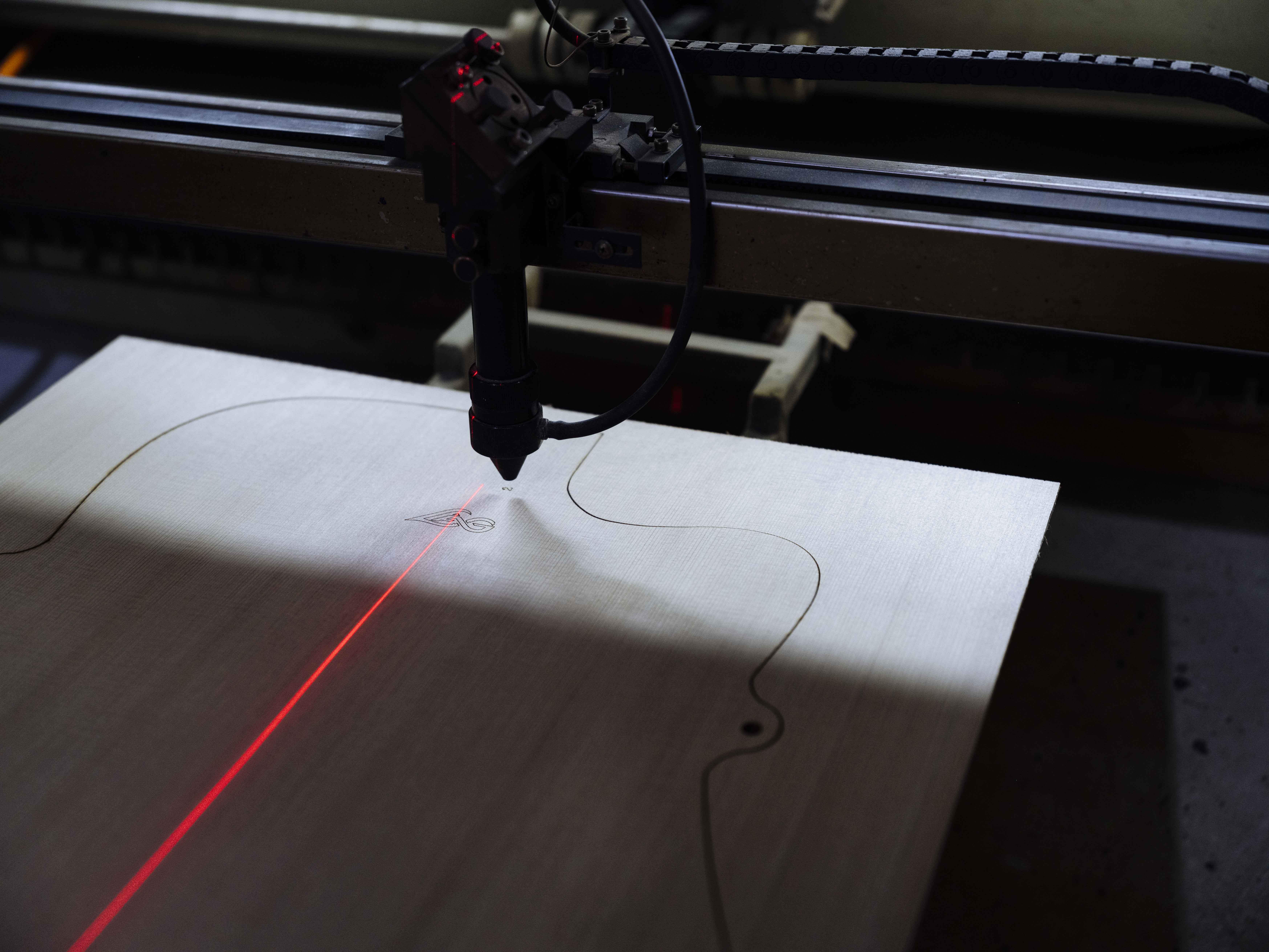

The rigorous control of humidity levels is a crucial factor in the guitar manufacturing process. The factory stands at the forefront of technology and innovation with its state-of-the-art machinery. The level of our finishes is a pivotal aspect of our guitar quality. Our UV treatment ensures optimal varnish drying to achieve linearity and robustness.

To achieve an ideal neck / body combination, another technique introduced by Maurice Dupont involves pairing each body with the neck that best suits its pocket. Optimizing this junction ensures both the quality of the tone and the reliability of the instrument's final setup.

To ensure impeccable quality, Lâg guitars undergo meticulous inspections before leaving the factory. Products are carefully assessed at various checkpoints within the factory and again in France. A dual, efficient quality control process for remarkable guitars.

VISIT OUR FACTORY

Français

Français

English

English

Deutsch

Deutsch

日本語

日本語